Precision for Professionals –

QNix® Coating Thickness Gauges

Every measurement has to be spot on. Sometimes it’s about paint, sometimes about protective coatings — but in all cases, accurate results are what matter most.

With QNix® coating thickness gauges, you measure quickly, safely, and without having to worry about settings.

Our devices are compact, durable, and streamlined to focus on what truly counts — so you can fully concentrate on your work.

The right solution for every measurement task.

QNix® offers a comprehensive range of coating thickness gauges tailored to various requirements. Each model impresses with easy handling and precise measurement results, ensuring you always have reliable data at your fingertips.

QNix® 1500

The classic in vehicle evaluation

Proven for vehicle evaluation and paint inspection.

No calibration required: simply place it, read the result, and you’re done.

QNix® 4500

All-rounder with a wide range of applications

Reliable results for a wide range of applications.

Compact design and one-button operation for quick and easy use.

QNix® 4600

The global player for added convenience

Perfect for frequent measurements.

The convenient color display rotates automatically and remains clearly visible even when upside down.

QNix® 5500

The easiest way to perfect measurement

Withstands dust, moisture, and harsh environments.

Interchangeable probes offer maximum flexibility on various materials (ferrous or non-ferrous).

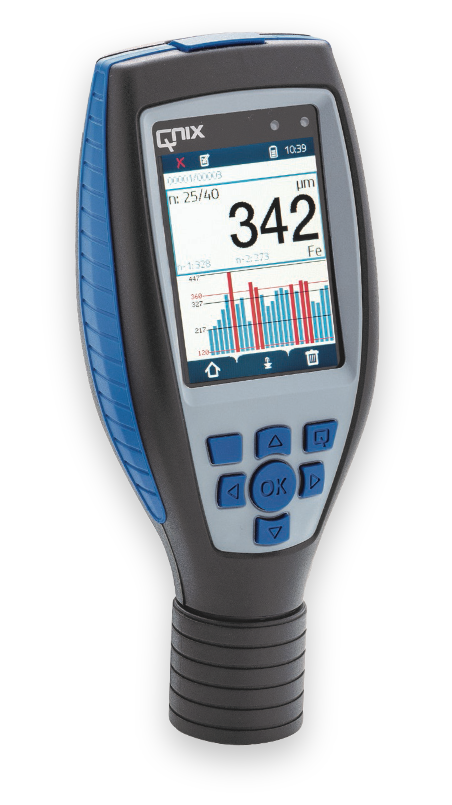

QNix® 9500

A field of application like no other

Captures even complex coating systems.

Offers extensive documentation options and integrated software for storing and analyzing data.

Why QNix®?

There are many measuring devices out there – but QNix® has been setting standards for over 50 years.

Our devices are handcrafted in Germany – Made in Germany with the highest precision and quality.

No complicated adjustments or calibrations needed – just place the device and start measuring right away.

They are robust, durable, and consistently reliable – whether in workshops, with appraisers, or in industrial settings.

Want advanced technology combined with ease of use and dependable results?

Then QNix® is exactly what you need for your coating thickness measurement.

All QNix® benefits at a glance:

- Simple: put on – measure – read off

- High accuracy and precision

- Simple zero point adjustment

- Durable ruby measuring head tip

Product information

Why QNix® is the best choice for your industry

Our handcrafted measuring devices, made in Germany, are ideal for demanding applications and consistently deliver precise results.

Whether in the automotive industry, corrosion protection, or surface finishing – thanks to their IP64 protection rating, they remain reliable even in dusty and humid environments.

Their intuitive operation ensures quick and reliable measurement results, saving you valuable time.

At the same time, they reduce the risk of measurement errors and help ensure efficient workflows in your operations.

Get expert advice – Find your perfect measuring device

Which device best suits your application? Our experts are happy to help.

Use our support request form or give us a call: +49 (0)221 91 74 55-0.

Overview and key features of our coating thickness gauges

QNix® 1500

Materials

Steel, aluminum, copper, zinc

Measuring range

0–5000 µm

Application areas

Automotive, Corrosion protection

Special features

Easy measurement without calibration, ergonomic design

QNix® 4500

Materials

Steel, Aluminum, Copper, Zinc

Measuring range

0–5000 µm (Fe), 0–3000 µm (NFe)

Application areas

Coating, Automotive, Standard applications

Special features

Easy operation, Hall sensor and eddy current technology

QNix® 4600

Materials

Steel, Aluminum, Copper, Zinc

Measuring range

0–5000 µm (Fe), 0–3000 µm (NFe)

Application areas

Vehicle assessment, Industrial coating

Special features

High measurement speed, automatic substrate selection

QNix® 5500

Materials

Steel, Aluminum, Copper, Zinc

Measuring range

0–5000 µm

Application areas

Corrosion protection, Vehicle assessment

Special features

Very robust, suitable for harsh environments, flexible probe options

QNix® 9500 Serie

Materials

Steel, Aluminum, Copper, Zinc

Measuring range

0–5000 µm (Fe), 0–3000 µm (NFe)

Application areas

Surface finishing, Industrial coating

Special features

High flexibility, software for documentation and reporting

Tips and tricks for your QNix®

Maximize the performance of your coating thickness gauge with useful application tips and practical guidance. Discover technical details, expert advice, helpful videos, and downloads. We provide everything you need to get the most out of your device.

The right device for every application

Coating thickness measurement is not one-size-fits-all. Each industry has its own requirements and unique challenges.

Our measuring devices are designed to meet these needs – helping you achieve precise results and document them quickly and reliably.

Whether you work in industrial manufacturing, shipbuilding, electroplating, or vehicle evaluation – we always have the right solution for your specific demands.

Which area of application interests you the most?

Measure precisely and non-destructively

With QNix® devices, you get accurate measurement results – without damaging the material.

The surface remains completely intact during measurement, while you receive fast and precise data.

Recommended by experts

Answers to frequently asked questions

Which Industries Are QNix® Coating Thickness Gauges Suitable For?

Our devices are used in many fields. This includes, for example, the metal industry—such as automotive manufacturing, railways, steel industry, mechanical engineering, shipbuilding, and aircraft construction. Our measuring devices are also in demand in the plastics and chemical industries. In electroplating, they are used for anodizing, chrome plating, or galvanizing. In addition, vehicle appraisers and paint shops (car dealerships, body shops, and experts) use our measuring devices. Maintenance and repair companies, as well as inspection organizations, also benefit from them. Finally, our devices are used in research and laboratory settings.

Can I Get Help Choosing the Right Device?

Yes, we are happy to support you. Are you looking for a simple device for the automotive sector? Or do you need a solution for demanding tasks in surface finishing? We will help you find the right QNix model. Link-Button: Kontakt

Yes, we are happy to support you. Are you looking for a simple device for the automotive sector? Or do you need a solution for demanding tasks in surface finishing? We will help you find the right QNix model. Contact

Are QNix® devices waterproof?

They are not suitable for underwater measurements. However, our devices are very robust and withstand demanding environments, such as in corrosion protection or shipbuilding. In addition, they are protected against dust and splashing water according to IP64.

Can the device measure on plastic or other non-metallic materials?

No. For such materials, we recommend an ultrasonic measuring device, which we do not currently offer in our range.

Does the measuring device need to be calibrated regularly?

There is no legal requirement for calibration. However, we recommend an annual inspection at our facility to ensure accuracy and to issue an up-to-date calibration certificate.

Can the devices measure on different materials?

Yes, our devices measure steel, aluminum, copper, and zinc. They are designed to be precise and easy to use. As a rule, no calibration or probe change is required.

Is there training or support available for the devices?

Yes, we offer training so you can make full use of our measuring devices. If you have any questions or issues, our support team is always available to assist you. Contact

Is the device delivered with batteries?

We deliver it with standard batteries. However, you can also easily use rechargeable batteries.

Which probe is suitable for very small geometries and measuring surfaces?

The QNix® 9500 with a pencil probe and customized user calibration is ideal for narrow or hard-to-reach areas.

Does surface roughness affect the measurements?

Yes, you should take that into account. With a model from QNix® 9500 Serie you can compensate for roughness using user calibration. A mean zero adjustment also provides more precise results here.

Can the devices measure on carbon (automotive)?

Unfortunately, that’s not possible. The rough structure of the material leads to inaccurate measurements.

What is the maximum surface temperature for coating thickness measurement devices?

Our devices cover a wide temperature range. They can be used at temperatures between -20 °C and +70 °C. Outside of this range, accuracy may decrease.

Which simple measuring device do you recommend?

The QNix® 4600 or the QNix® 5500 are robust entry-level models with easy operation and reliable results.

How is the data transmission carried out?

Via a USB interface cable. This connection has proven to be particularly secure and reliable.

Does the accuracy vary depending on the measuring range?

No, the accuracy remains the same regardless of the measuring range. You can find the exact values in our technical specifications.

Precision the industry relies on

Our coating thickness gauges take your production processes to the next level. They deliver precise measurements that help ensure quality and reduce costs. With QNix®, you can be confident that your measurements are reliable and your processes remain efficient.

Coating thickness measurement that delivers

Want to know how thick a coating layer is? Wondering if your product quality meets the mark? No problem – our devices show you the result instantly, without damaging the material. Whether it’s steel, aluminum, or other metallic surfaces, precise measurement ensures everything is just right. Avoid costly production errors that waste time and money.

Get in touch with us.

We look forward to hearing from you.

Simply select the relevant topic and let us know how we can assist you. Our team will get in touch with you promptly and answer all your questions.

Your contact person

Metin Tek

Director Sales & Marketing

Head of Sales & Marketing

Tel: +49 221 91 74 55-23

Mobile: +49 160 92 75 69 97

E-Mail: m.tek@automation.de