QNix® 9500

The coating thickness gauge for coating control on metal.

QNix® 9500 is our recommendation for industrial coatings,

Surface finishing and heavy-duty corrosion protection

Coating thickness measurement made better: See for yourself!

Do you have just 10 minutes to spare and want to find out more about our coating thickness gauges? In our information video we present

We would like to introduce you to our latest generation of coating thickness gauges – the QNix® 9500 and QNix® 5500 – and their areas of application.

A coating thickness gauge for coating control on metal

Let us convince you of the features, advantages and technical data of the new QNix® 9500 We are sure to provide you with added value for your measuring tasks Quality and service are and will remain our top priority

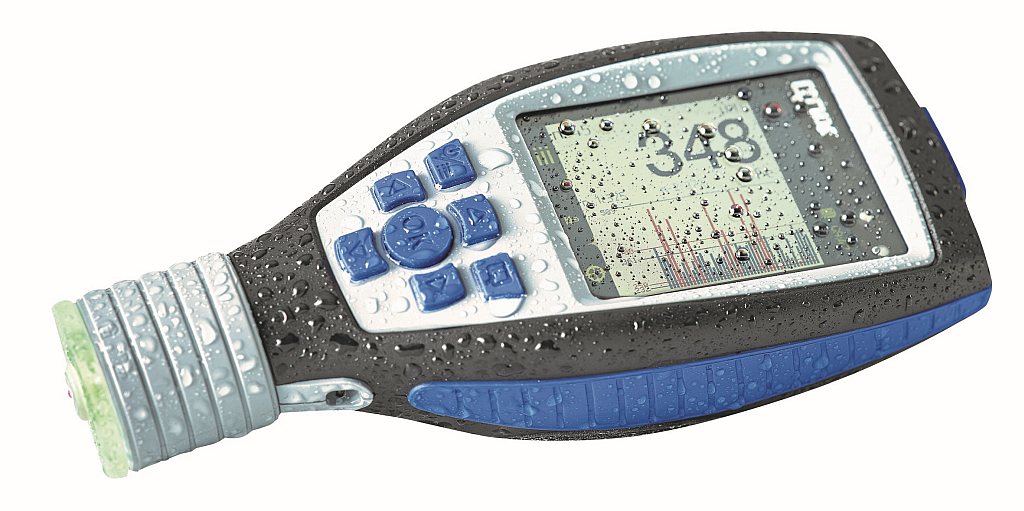

QNix® 9500 measuring device

QNix® 9500 probe

QNix® 9500 Software

QNix® 9500 measuring device

Safety through precision and accuracy

For valid measurement results in your quality assurance

- High accuracy over the entire measuring range

- High repeatability of measurement results

- Easy adjustment on rough, smooth or curved substrates

Robustness and resistance

For long and reliable use, even under harsh conditions

- Fiberglass-reinforced, five-part housing with IP65 dust and splash water protection

- Three-layer protection to absorb shocks

- LCD screen made of scratch-resistant, chemical-resistant* glass (level H6)

- Operating temperature from -20 °C to +70 °C

Saving time through ergonomics

Fast and fatigue-free working, even in continuous operation

- Direct feedback via limit value indication on the display and RGB LED on the probe

- Bright IPS LCD, 2.4″, color, 600 lm, reading angle 70°

- Optimum readability even in direct sunlight, automatic or manual brightness adjustment

- Flipping display 0°, 90°, 180°, 270°. Automatic or manual

- Large, tactile buttons and low device center of gravity

Flexibility and expandability

Future-proof thanks to interchangeable probes

- Hand-held device suitable for Fe, LFe and dual probes

- Quick change to cable probes

- Integrated probe and cable probe available in one device

- Increased operational readiness thanks to quick probe changes

- Quick adaptation to different measuring tasks

Comprehensibility and user-friendliness

Intuitive operation that saves time and money

- Simple adjustment

- Intuitive menu navigation in handheld device and software, 3-clicks to report

- Freely assignable button for individual quick access

- Preconfigured norms and standards

QNix® 9500 probe

3rd generation digital probe

RGB LED limit value display

- Temperature compensation directly in the sensor

- Direct feedback via limit value display in the hand-held device display and RGB LED* on the probe (*only with modular hand-held device variant)

- The measurement technology is completely built into the probe – see also: Is the measurement technology dependent on the handheld unit?

- Digital calibration certificate on the probe – see: Why is there a digital copy of the calibration certificate on the probe?

The QNix® 9500 with integrated probe

an economic compromise

- The following probes are available for the integrated version of the QNix® 9500 – see: Which probes are available for the QNix® 9500?

- The integrated version is also available as Basic, Premium and Premium +

- It is not possible to change the probe or connect the probe adapter cable

- The RGB LED limit value display on the probe is not available

The QNix® 9500 with modular probe

Maximum flexibility

- Simple probe replacement – see: How can the probes of the modular version be changed?

- The following probes are available for the modular version of the QNix® 9500 – see: Which probes are available for the QNix® 9500?

- Adaptation to a wide variety of measurement situations

Smallest QNix® measuring probe

Also for small and hard-to-reach measuring surfaces

- Precise measurements even on curves and small parts

- Smallest radius of curvature convex Fe 6 mm, NFe 70 mm with zero point adjustment (normalization to zero)

- Smallest thickness of the base material Fe: 0.2 mm, NFe: 0.05 mm

- Smallest measuring surface 14.5 mm

- Weight 11.9 g

The probe adapter cable

Quick change between integrated probe and cable probe

- Probe adapter cable made from drag chain-compatible PUR

- See: How can the probe adapter cable be used?

Extremely robust

For long and reliable use (IP65)

- Stainless steel probes with dust protection membrane (IP65)

- Robust measuring head with polished ruby

- Chemical-resistant material for cleaning with solvents (acetone, nitro thinner) – see also: How do I clean the QNix® 9500 properly?

QNix® 9500 Software

The report editor

Quick and uncomplicated report

- Creation of individual report templates via drag-and-drop

- Integration of logos, photos of the measurement object and the last calibration certificate (located digitally on the probe)

- Preconfigured and freely positionable text, table and graphic modules

Report in 3 clicks

Saving time in documentation

- The integrated, powerful statistics functions allow you to analyze your measurements with just three clicks – see also: How do I create a report in 3 clicks with the QN9 software?

Live measurement

Show measurement results in large format

- Live measurement via the QN9 software, also possible on a separate monitor

- Limit value display on the monitor, the hand-held device and the RGB LED* on the probe (*only for modular hand-held device variant)

High usability

Intuitive, easy to understand

- Browser-based and independent of the current Windows version

- Graphical user interface

Device configuration

Convenient and time-saving

- Creation of jobs and areas with individual naming

- Defining limit value settings for each job

- Configuration of the system, display, limit value and probe settings

The QNix® 9500 product family

| Functions | Basic | Premium | Premium+ |

|---|---|---|---|

| Color LCD | ✓ | ✓ | ✓ |

| Adjustable display resolution | ✓ | ✓ | ✓ |

| Rotatable display: 0°, 90°, 180°, 270°, automatic and manual | ✓ | ✓ | ✓ |

| Automatic brightness adjustment | ✓ | ✓ | ✓ |

| Manual brightness adjustment | ✓ | ✓ | ✓ |

| Acoustic measurement confirmation, volume adjustable | ✓ | ✓ | ✓ |

| Switching between µm and mil | ✓ | ✓ | ✓ |

| Battery replacement without loss of settings, date, and time | ✓ | ✓ | ✓ |

| Live display of statistics as values | ✓ | ✓ | ✓ |

| Display statistics as a graph | ✓ | ✓ | ✓ |

| Live measurement (display measurement values on PC) | ✓ | ✓ | ✓ |

| Customizable hotkey | Fix Start Just | ✓ | ✓ |

| Accurate measurement (delayed measurement upon contact) | – | ✓ | ✓ |

| Measurement trigger via button (adjustable) | – | ✓ | ✓ |

| Pin protection | – | ✓ | ✓ |

| Functions | Basic | Premium | Premium+ |

|---|---|---|---|

| Automatic substrate switching | ✓ | ✓ | ✓ |

| Manual substrate switching | ✓ | ✓ | ✓ |

| Combined measurement (Fe and NFe coatings with a single measurement) | – | ✓ | ✓ |

| Measurement speed: single measurements per minute | ≥ 120 | ≥ 120 | ≥ 120 |

| Continuous measurement mode | ✓ | ✓ |

| Functions | Basic | Premium | Premium+ |

|---|---|---|---|

| Einsatzbereich Temperatur | ✓ | ✓ | ✓ |

| IP rating | IP65 | IP65 | IP65 |

| Operating temperature range | -20 °C bis 70 °C | -20 °C bis 70 °C | -20 °C bis 70 °C |

| Functions | Basic | Premium | Premium+ |

|---|---|---|---|

| USB | ✓ | ✓ | ✓ |

| QN9-Software | ✓ | ✓ | ✓ |

| Functions | Basic | Premium | Premium+ |

|---|---|---|---|

| Zero adjustment | ✓ | ✓ | ✓ |

| 1-point | ✓ | ✓ | ✓ |

| 2-point | ✓ | ✓ | ✓ |

| Custom (freely configurable calibration) | – | ✓ | ✓ |

| Device calibration memory (10 calibrations) | – | ✓ | ✓ |

| ISO 19840 Zero Offset | – | – | ✓ |

| ISO 19840 2-Point | – | – | ✓ |

| SSPC PA2 Zero Offset | – | – | ✓ |

| SSPC PA2 2-Point | – | – | ✓ |

| Functions | Basic | Premium | Premium+ |

|---|---|---|---|

| Area switching | – | ✓ | ✓ |

| Copy jobs / areas | – | ✓ | ✓ |

| Jobs | 1 | 1 | 100 |

| Areas pro job | 1 | 100 | 100 |

| Spots pro area | 10.000 | 10.000 | 10.000 |

| Total Memory | 10.000 | 1.000.000 | 2.000.000 |

| Functions | Basic | Premium | Premium+ |

|---|---|---|---|

| Adjustable limit values | ✓ | ✓ | ✓ |

| Indicate limit value exceedance via LED | ✓ | ✓ | ✓ |

| Limit values per area | – | ✓ | ✓ |

| Automatic area switching (AAW) | – | ✓ | ✓ |

| Custom | – | ✓ | ✓ |

| ISO 19840 | – | – | ✓ |

| SSPC PA2 (80/120) (Level 1-5) | – | – | ✓ |

| IMO PSPC (90/10) | – | – | ✓ |

Our product range

With its QNix® brand, Automation Dr. Nix offers a wide range of coating thickness gauges for the non-destructive measurement of coatings for a wide variety of applications in a wide range of industries.

QNix® 9500

Highly accurate and extremely robust coating thickness gauge. Ideally suited for measurement tasks with requirements for measured value storage, archiving, creation of documentation & reports and device configurations.

QNix® 5500

The optimum device for quick and easy checking of coating thickness. Handy, precise, extremely robust, designed for continuous use and very user-friendly. Simply switch on, put on, read off

QNix® 4500 / 4200

Universal, tried and tested and reliable. Wide range of applications and easy handling.

QNix® 1500

The classic coating knife. Very popular with motor vehicle experts, especially proven for larger measuring areas. With automatic on/off and one-hand operation.