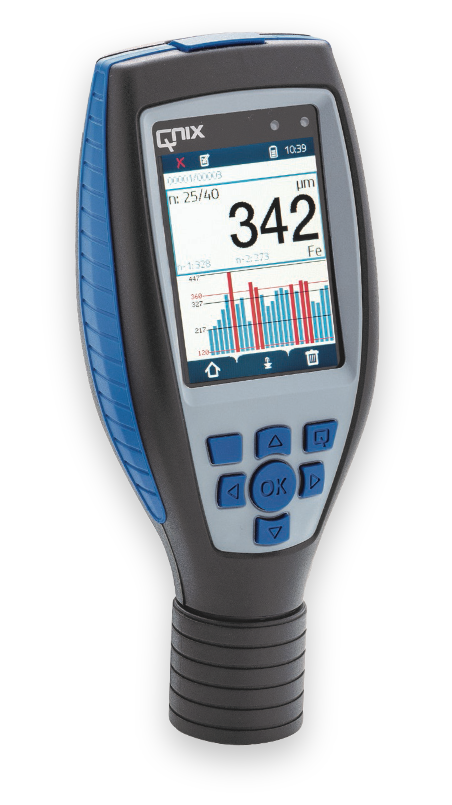

The basis for secure and intelligent documentation is the structured measurement data storage of the QNix® 9500. The measurement data is stored by batch, component, measuring range, vehicle, vehicle part or order number, for example, by creating so-called “jobs” and “areas”.

Each individual area can be set and preconfigured individually with different settings for adjustments, standards, limit values, number of measurements and automatic switching or automatic creation of areas. You can save the settings and transfer them to one or more devices. It is also possible to lock the settings using a PIN. The devices are prepared for specific measuring tasks and guide the user through the measuring task. This enables you to achieve a high level of process reliability.

Finally, the measurement results incl. of the most important settings very simply and quickly summarized and documented in a report. The reports are freely editable and can therefore be designed according to your requirements. Preconfigured and freely positionable text, table and graphic modules allow you to create report templates using drag-and-drop. Logos, photos, drawings and graphics of the measurement objects can also be easily integrated.

Image source: :i/i/d Institute for Integrated Design Bremen

Read on, use our support form or give us a call – we will be happy to advise you: +49 (0)221 91 74 55-0

Automation Dr. Nix GmbH & Co KG

Robert-Perthel-Strasse 2

50739 Cologne

Phone: +49 (0)221 91 74 55-0

info@automation.de