Industrielackierung: Perfekter Schutz,

perfekte Optik

Paint is much more than just color. In industry, it protects components from wear, corrosion, and environmental influences. At the same time, it gives products a flawless finish. But for a coating to work optimally, the layer thickness must be just right. Too thin – and the protection is insufficient. Too thick – and unnecessary costs arise, plus the coating quality can suffer.

This is especially challenging in serial production. Even small fluctuations and deviations in the paint can quickly add up. If a single component is not coated correctly, it’s frustrating. But when hundreds or thousands of parts on a production line are affected, costs can escalate—due to rework or parts that can no longer be salvaged. That’s why precise coating thickness is particularly important here. The coating must always be consistent and efficient. Materials, machines, and coating processes—all must be perfectly coordinated to minimize errors. Reliable coating thickness measurement ensures that each layer is applied exactly as required.

QNix® Coating Thickness Gauges for Industrial Coating

QNix® 5500

- Extremely durable: Protects against dust and splashing water – perfect for tough everyday use

- Fast and efficient: Quicker measurements thanks to automatic material detection

- Compact: Easy one-handed operation with a rotatable display

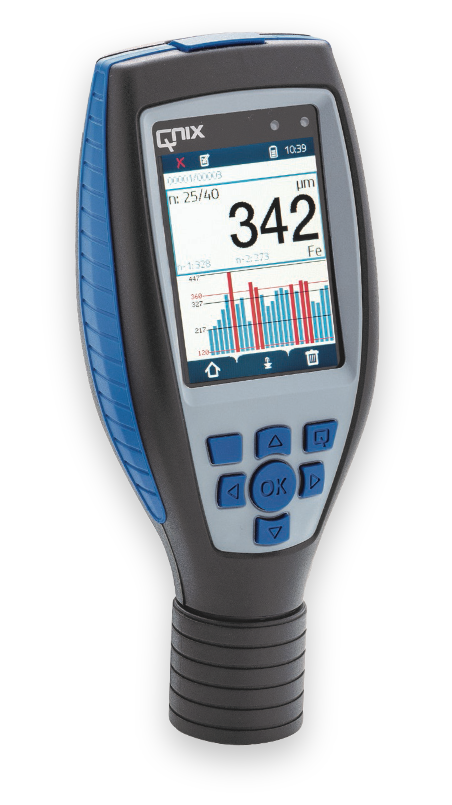

QNix® 9500

- Fast and precise: Also measures complex coating systems – ideal for demanding applications

- Flexible and easy to use: Modular design with interchangeable probes and user-friendly operation

- Perfect documentation: The integrated software lets you create custom reports and keep everything in view

Where industrial coating plays a key role

Paint is more than just color—it protects, strengthens, and makes products durable. However, each industry has its own requirements and follows its own approach to quality assurance. In the automotive industry, paint must withstand impacts, stone chips, and extreme temperatures. In mechanical engineering, corrosion protection is key to ensuring components work reliably for years. In aerospace, every gram counts, even though conditions can be extreme. Here, coatings must be extremely lightweight while also highly resistant.

In the construction sector, paint is not used merely for decoration. After all, facade coatings are designed to withstand wind and weather, while steel structures are protected from rust with the appropriate paint. But this only works if the coating has an optimal thickness.

Why is coating thickness measurement so important in industrial coating?

Standards and regulations in industrial coating

Challenges in industrial coating

Painting is not just about “putting on the color and done.” Every coating must fit precisely. After all, it should protect, be economical, and sometimes also look good. But in practice, there are several obstacles that complicate the painting process.

What type of coating is used? Wet paint or powder coating? Each process comes with its own challenges.

Wet paints change their thickness during drying. What initially looks perfect can end up being too thin or too thick. This affects not only protection but also appearance. Powder coatings, on the other hand, must be evenly distributed before curing. If the layer is uneven, the defect remains after hardening—correction is then hardly possible. Especially in the automotive or aerospace industries, tolerances are minimal. Every component must have exactly the same coating thickness; otherwise, there is a risk of scrap, rework, and additional costs.

Answers to frequently asked questions

Why is coating thickness measurement important in industrial coating?

Paint protects against rust, weather, and wear—but only if the coating thickness is just right. If it’s too thin, protection is lacking. If it’s too thick, cracks can form or excessive material is used unnecessarily.

Which measuring devices are suitable for industrial coating?

For precise measurements, the QNix® 9500 and QNix® 5500 are the ideal choice. The QNix® 9500 is suited for complex coatings and offers maximum flexibility with interchangeable probes. The QNix® 5500 is perfect for quick, simple measurements in production. Both devices are easy to use, deliver accurate results, and help save time and material.

Can I Get Help Choosing the Right Device?

Yes, we are happy to support you. Are you looking for a simple device for the automotive sector? Or do you need a solution for demanding tasks in surface finishing? We will help you find the right QNix® model.

Are QNix® devices waterproof?

They are not suitable for underwater measurements. However, our devices are very robust and withstand demanding environments, such as in corrosion protection or shipbuilding. In addition, they are protected against dust and splashing water according to IP64.

Does the measuring device need to be calibrated regularly?

There is no legal requirement for calibration. However, we recommend an annual inspection at our facility to ensure accuracy and to issue an up-to-date calibration certificate.

Can the devices measure on different materials?

Yes, our devices measure steel, aluminum, copper, and zinc. They are designed to be precise and easy to use. As a rule, no calibration or probe change is required.

Is there training or support available for the devices?

Yes, we offer training so you can make full use of our measuring devices. If you have any questions or issues, our support team is always available to assist you. Contact

Which probe is suitable for very small geometries and measuring surfaces?

The QNix® 9500 with a pencil probe and customized user calibration is ideal for narrow or hard-to-reach areas.

What is the maximum surface temperature for coating thickness measurement devices?

Our devices cover a wide temperature range. They can be used at temperatures between -20 °C and +70 °C. Outside of this range, accuracy may decrease.

Does the accuracy vary depending on the measuring range?

No, the accuracy remains the same regardless of the measuring range. You can find the exact values in our technical specifications.

Which typical paint defects can be detected with a coating thickness gauge?

Yes, they can be repaired by our customer service team. Manufacturers usually paint a car with a uniform thickness. If the device measures significantly higher values in some areas, this indicates repainting or filler work. This way, you can tell whether the paint is still original.

Can a coating thickness gauge distinguish between original paint and repainted areas?

Yes, they can be repaired by our customer service team. Manufacturers usually paint a car with a uniform thickness. If the device measures significantly higher values in some areas, this indicates repainting or filler work. This way, you can tell whether the paint is still original.

What advantages do QNix® coating thickness gauges offer for vehicle assessment?

With QNix® devices, you can measure paint layers quickly and accurately. They are easy to use and suitable for various substrates (steel and aluminum). Additionally, they comply with international standards and provide reliable data—a solid foundation for confident vehicle assessments.

Get in touch with us.

We look forward to hearing from you.

Simply select the relevant topic and let us know how we can assist you. Our team will get in touch with you promptly and answer all your questions.

Your contact person

Metin Tek

Director Sales & Marketing

Head of Sales & Marketing

Tel: +49 221 91 74 55-23

Mobile: +49 160 92 75 69 97

E-Mail: m.tek@automation.de